TRANSFORMERS

Our experience in the field has enabled us to solve a wide range of requirements even for special units, i.e. converter transformers with 6-12-18-24-36 pulse, earthling transformers with and without auxiliaries, transformers for solar plants with 1-2-3 secondary windings, HV/HV transformers, multi voltage transformers, transformers with different type of oil: Silicon type, MIDEL, FR3. Shunt reactors, current limiting, damping, tuning (filter), arc-suppression, smoothing reactors, LV/MV/HV reactors up to 52 kV.

SIM Switchgear are present in the national and international market . The recently built new works are equipped with high-tech producing plants, the most sophisticated automation job order systems via real time production management.

In a continuously expanding and developing world where it is required to be competitive and dynamic in every market, the company shall give evidence of its skills providing constantly state of art products that fulfils the markets’ request.

Being in the business as we put it here in SIM does not lie as much in waiting for replies from the market, but rather in proposing themselves, understanding the demands, evaluating the needs and at the customers’ side offering more than required by constantly calling themselves into question so to increase and improve.

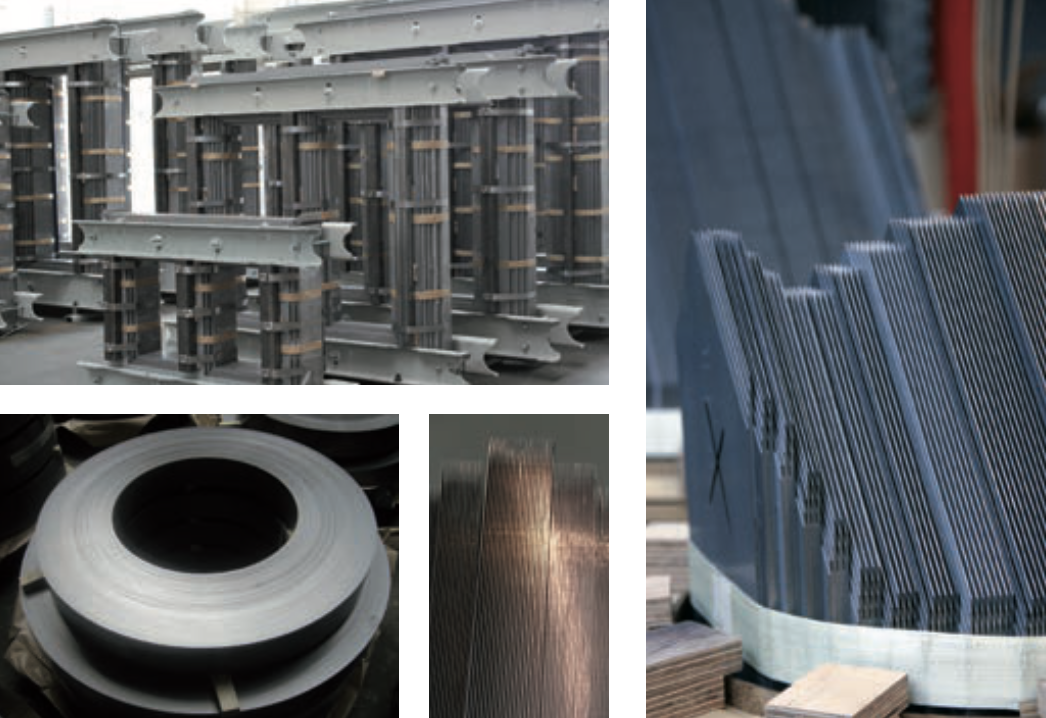

The transformers cores are obtained from cold rolled grain oriented (CRGO) magnetic steel sheets with highly magnetic permeability and insulated on both sides with a thin layer of inorganic material (Carlyte). The sheet cut and the composition at 45° with “Step Lap” intercalated joints guarantee reduced no-load losses, reduced idling current and low noise level. The number of steps and the magnetic induction are optimized for the power of the transformer. The top and bottom clamps are made by galvanized steel designed as to guarantee the necessary strength for all movements during transport and unloading, electro dynamic stresses and the most difficult installations.

The transformer windings are concentric and coaxial to the core limbs. The windings are made of copper or aluminum with insulation material in class A or F. Channels in the windings guarantee oil circulation and windings optimal cooling.

All transformers up to 3150 kVA are equipped with corrugated tank wall panels. Higher power units use special developed radiators made with cold rolled and laminated steel. All transformers up to 3150 kVA can be filled without conservator.

The outside walls are protected with water resistant paint RAL 7031 or RAL 7033 with painting thickness of minimum 100 micron.

The primary and secondary windings are made with electrolytic aluminum or copper, with insulation in pure cellulose paper or in double enamel for wires of small diameter. These windings are oval or circular section and are a concentric type, coaxial to the core columns. The high voltage winding is made with a wire or a metal strip, helically wound with more layers or with continuous disc in relationship to the working voltage and the transformer’s power. The low voltage windings are made with foil or strip and are equipped with terminal bars welded along the whole coil length in order to guarantee the correct sturdiness and electro-mechanical stress. Each winding layer of low and medium voltage is insulated with pure cellulose paper, the oil’s circulation and necessary cooling are assured by wide channels placed between the windings layers. Insulation between high and low voltage and between the latter and the core is made with compressed cardboard cylinders with a well-sized thickness.

The adjustment or variation of primary voltage is done with linear tap changers in an oil bath and maneuverable with the transformer disconnected from the network by using knobs placed on the cover. To avoid an incorrect positioning of the tap- changers, are foreseen some holes in correspondence with each indication notch of the various positions that allow a secure housing of the knob; in addition, it is possible to apply a padlock to avoid accidental or unauthorized maneuvers.

If required, the transformer may also be equipped with on-load tap changer, which regulates the voltage variation with working (energized) transformer. SIM Switchgear offer transformers equipped with any make of on-load tap changer in the market also for small power range.

The high and low voltage bushings are oil filled type in enameled brown porcelain according IEC standards. The insulators are fixed on the conver with special frames and and may be substituted without removing the core and coil assembly. High voltage bushings may be equipped on request with spark gap rods. The high voltage bushings are provided with spark grip rods. Cast resin insulators suitable for Elastimold type connectors can be delivered upon request.

For the whole range of SIM oil immersed products we have studied, developed and designed new gaskets for outdoor installation bushings that are: from -60°C, -40°C, -25°C up to 120°C or 150°C.

The filling of the transformers is obtained with mineral oil, without PBC, dried and degassed, with electrical and chemical specifications, which conform to the CEI and IEC standards; the filling is done under-vacuum for the best oil electrical rigidity withstand. If required the tank can be filled with silicon type dialectric oil, MIDEL or FR3

All our transformers are equipped with following standard accessories:

- Oil conservator mounted on the tank top cover (for non hermetically sealed transformers)

- Oil level indicator on the conservator

(for non hermetically sealed transformers) - MV regulation tappings ± 2×2,5% wired to

off-circuit tap changing switch with external

operating handle - MV screwed, fully insulated porcelain bushings, 3

off, (DIN 42 531) requirements - LV Porcelain bushings, 3 off line terminals plus

Neutral bushing, (DIN 42530) requirements - Oil filler cap

- Oil drain valve (DIN 42 551) requirements

- n°4 bi-directional floor rollers (DIN 42 561)

requirements - n°1 rating and name plate (IEC 60076)

requirements - Lifting lugs/eyebolts

- n°2 earthing terminals

- Thermometer pocket in accordance (DIN 42 554)

The transformer tank is available in two versions: corrugated (finned) tank or with radiators, made with cold rolled and laminated steel. All radiators are singularly tested before their assembling. If required the transformer may be supplied with a traditional expansion conservator. All transformers up to 4000 KV can be filled without conservator. The inside walls of tanks are protected, prior to sand blasting, with special paint insoluble to hot oil. The outside walls are protected with water resistant paint RAL 7031 or RAL 7033 with painting thickness of 100- 120 micron, suitable to the strictest environmental conditions.

On request following additional accessories can be delivered:

- Gas and oil operated Buchholz relay with 2

electrical contacts - Dehydrating breather (for non hermetically sealed

transformers) - Oil level indicator contacts on the conservator

(for non hermetically sealed transformers) - Pressure relief valve (hermetically sealed

transformers) - Protection system DGPT2 or RIS (for hermetically

sealed transformers) - Thermometer with 2 electrical contacts

- Protection housing IP 55 for LV bushings

- Protection housing IP 55 for MV bushings

- Antivibration pads for wheels

- Pressure relay with 2 electrical contacts

- Electrostatic screen between primary and

secondary voltage - Skids for pole mounted transformers